Folding RFR

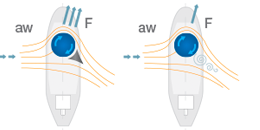

RFR-THiiiNK has developed new patented technologies to optimise performance

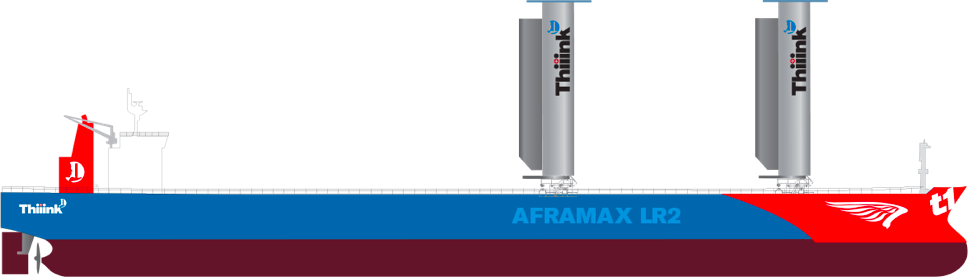

The THiiiNK folding RFR Rotor Flap Flettner rotors can be hydraulically folded onto a vessel’s deck. This provides easier access to ports, the ability to navigate bridges, the ability to stow the rotors in adverse weather conditions whilst at sea. It also minimises interference with loading of cargoes and other operations at port.

Note: THiiiNKsail© RFR Rotor Flap Flettner rotors are made of non flammable steel aluminium, like tested on ESHIP1, for transport of explosive cargo’s at sea.

Accidents Statistics composite wind power plants:

From 2011 to 2016 alone: 140 blade failure reports, including 111 fires, clearly show, all composites advantages, are gone compared to steel or aluminium, once the fire starts it’s unstoppable by normal means for the crew, when mixing highly flammable composits & machinery!

See full accident report composite Wind-Turbines!